PROGRAM CAPABILITIES

Providing you with a full suite of inventory management programs.

Inventory is often a company's largest asset. Trinity offers flexible Inventory Management solutions with many optional features that effectively manage your C and D class components. Our ISO certified programs are tailor made to fit your need, improve your bottom line and increase your overall production.

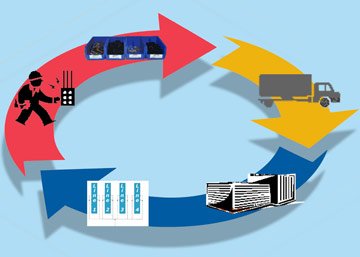

Supply chain solutions that streamline your production lines are our main focus. Whether you prefer a dock drop, line-side delivery or any plant destination in between, Trinity can adjust our programs as needed to support your production and assembly lines. Take advantage of the following vendor managed inventory (VMI) programs that are personalized to suit an OEM's unique needs and offer complete responsibility for hardware supply:

Let Trinity be your single source supplier

LINEBACKER

Multi-bin Kanban process

Trinity's vendor-managed inventory (VMI) Linebacker Program utilizes a multi-bin kanban process that enables assembly lines to run smoother and more cost-effectively. Pre-panned products are delivered directly to a given line or support location on a pre-determined schedule providing you a single source supplier for all types of fasteners, hydraulic fittings, hoses and more.

- reusable containers

- mid-size bulk containers

- packaged material

- sub assembled components

- kitted material

- pallet containers

- KANBAN SELECT

- Consignment Program

This is a unique kanban program that takes the hassle out of managing consignment inventory. Trinity will manage the delivery scheduling from your suppliers, receive and store your products and then deliver to you or direct ship to your customers. Combine this program with customized packaging and private labeling for a full service consignment replenishment program.

The Kanban Select program can be customized for a seamless transition from your consigned material to Trinity owned material or from one supplier to another as needed. This ensures you will never be overstocked or out of stock again. Let Trinity manage your consignment inventory program.

SCAN SWIFT

Self-Directed Inventory Program

Scan Swift is a self-directed inventory solution that will streamline your Maintenance and Repair (MRO) inventory process. Using barcode labels and a mobile scanning device, this automated turn-key system makes it easier than ever to manage and re-order the parts you use every day. This convenient replenishment program puts you in control of what is ordered and when it is ordered. Scan Swift's mobile, portable set-up makes your ordering system quick and efficient.

The Scan Swift program can also be customized to have a knowledgeable Trinity professional visit your site and utilize mobile scanning technology to replenish and reorder hardware to save you time and money.

Our inventory programs provide for easy ordering for manufacturing and MRO material in tool cribs, storerooms, multiple storage units, inventory stored in multiple locations and any number of point-of-use (POU) locations. We create line-side ready products and assemblies and deliver them when and where you need them.

With cost-effective programs, years of experience, and fast, efficient service you can expect the best from Trinity. For more information on any of our services, contact us! We look forward to helping you find a solution to your inventory problems.